Precision Printing Backed by Industry-Leading Tech

At S3D NZ, we use the Bambu Lab P1S with AMS to deliver fast, high-quality, multi-material prints—perfect for tradies, workshops, and industrial jobs that demand durability, detail, and speed.

Our 3D Printing Technology

Powered by Bambu Lab. Built for Kiwi Workplaces.

At S3D NZ, we use the Bambu Lab P1S with AMS (Automatic Material System) to deliver fast, precise, and high-quality prints. This advanced setup allows us to produce durable, functional parts in single or multi-material jobs—ideal for trade, workshop, and industrial use.

Why We Use the Bambu Lab

High-Speed. High-Precision. High-Performance.

The Bambu Lab P1S is a professional-grade 3D printer designed for real-world use. It delivers accurate, strong parts at high speed—making it ideal for bulk production, one-off custom jobs, or detailed prototypes.

We chose the P1S because it consistently delivers the results our clients expect:

Clean finishes

Fast print speeds

Excellent layer bonding

Reliable performance under pressure

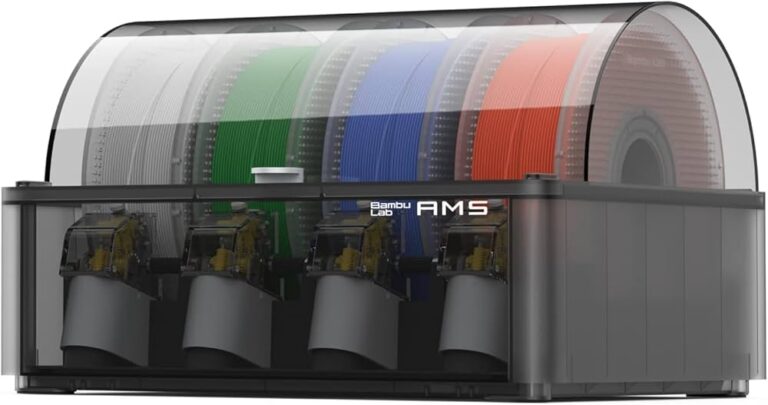

Multi-Material Printing with AMS

Need Multi-Colour or Multi-Material Prints? No Problem.

Our Automatic Material System (AMS) allows us to print with up to four colours or materials in a single job—perfect for branded parts, functional prototypes, or parts requiring multiple properties (e.g. flexible + rigid sections).

Whether you’re prototyping a product or want custom colour-coded trays or jigs for your toolkit—we’ve got the flexibility to print it.

What We Can Print With

Trusted Materials for Practical Use

We work with a carefully selected range of premium materials to suit your project needs:

PLA – Reliable, affordable, general-purpose strength

PLA+ – Tougher, impact-resistant parts for heavier workshop use

PETG – Flexible, durable, and suitable for mild outdoor exposure

ABS – High-heat, high-impact durability for industrial environments

TPU – Flexible, rubber-like material for protective parts and grips

We use proven materials from some of the world’s best filament manufacturers:

Bambu Labs – Consistently high-quality filaments optimised for speed and strength

eSun – Industrial-grade filaments known for reliable, clean results across a wide range of applications

Need a specific material for a specialist project? Let us know—we can help source and test it for you.

Ideal for:

Custom workshop accessories

Brackets, trays, clips, covers

Engineering prototypes

Low-volume or High-volume production runs

Trade tool and vehicle organisation

Parts requiring visual colour separation or branding

Why Our Parts Work

Built to Work. Printed to Last.

Designed with Kiwi tradies and workshops in mind

Printed using high-quality PLA+ for toughness and durability

Easy to mount, install, and use straight away

Made locally in Christchurch with fast turnaround

No overseas shipping delays or cheap plastic knock-offs

Get the Right Print for the Right Job

We’ll Recommend the Right Material Based on Your Use Case

Not sure what material or type of print is best for your job? Just tell us what you need it for, and we’ll recommend the best option based on durability, strength, flexibility, and cost.